PRODUCT

01Mask Blanks

A mask blank is a glass substrate coated with a metal film and a photosensitive film.

When circuit patterns are formed on these masks, they are called photomasks. They are used to manufacture complex electronic circuits for flat-screen television screens, computers, smartphones, and other devices.

Comparing a photomask to a photographic negative, the mask blank is like film before being exposed to take a photograph, and they are truly indispensable in the development and manufacture of multifunctional electronic products.

Boards and Specifications

-

〇Board types

Soda glass or synthetic quartz is mainly used, but non-alkali and other base materials are also available.

〇Board sizes

We can accommodate small sizes of 2.5" up to ultra-large sizes exceeding 1 m in length. Please contact us for sizes not included in the Compatible Size List.

〇Film types

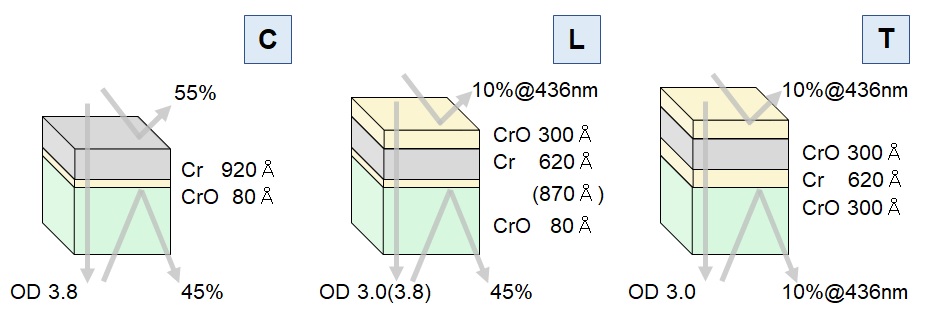

Cr single-layer films (C in the figure), low-reflection two-layer films (L in the figure), low-reflection three-layer films on front and back surfaces (T in the figure), and others.

Film thickness and optical characteristics can be modified or adjusted as needed.

〇Resist coatings

In addition to AZ P 1350, which is the most commonly used coating in photolithography, we can also provide highly sensitive AZ 1500 and GRX-M237 coatings.

Fringe-Small (FS) coatings using our technology ensure a wider patterning area and stable quality with good surface distributions. -

CST Mask Blanks

-

Our Extensive Lineup and Capabilities

We can provide a wide variety of sizes to meet your diverse needs.

We can also suggest products meeting needs for sizes other than our regular lineup with proposals based on our many years of experience.

We accept orders from small lots for initial prototyping and evaluation.

We have multiple production lines, so you can also trust your mass production needs to us. -

Extensive Quality Control and Improvement Initiatives

In response to the ever-increasing demands for quality in recent years, we are increasingly focusing on quality control.

We have established systems for continuous quality improvement by monitoring manufacturing environments and washing lines to reduce pinholes, particles, and other defects. -

Film Designs with Superior Properties

Variances in reflectance, density, and other optical properties are small and stable.

Our films are designed with a thin layer of chromium oxide on a CST-standard base and engineered to reduce defects arising from temporal changes in soda-lime glass, enhance adhesion onto the glass, reduce film stress, and other effects. -

Fringe-Small (FS) Coatings

FS coatings reduce resist-rise widths at the periphery, which inevitably occurs during spin coating, expanding the pattern area and achieving excellent uniformity.